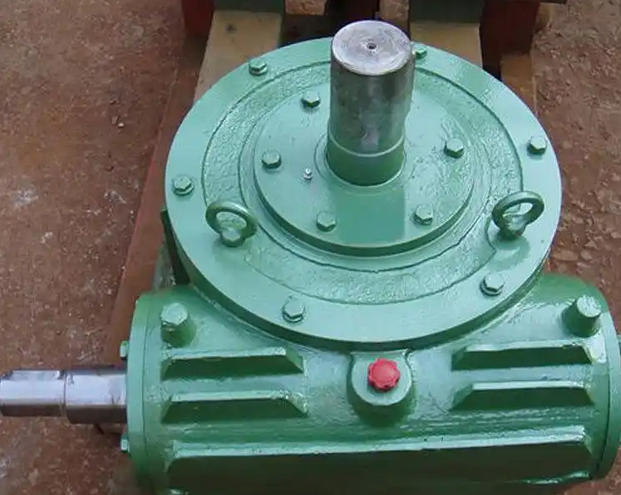

Application and selection of K107 reducer in sewage treatment equipment

In sewage treatment equipment, K107 reducer plays an important role in providing support for the stable operation and efficient treatment of the equipment. When selecting a reducer for a newly built urban sewage treatment plant, the mixing device for the biochemical reaction tank was comprehensively considered, taking into account the size of the tank, the characteristics of the mixing medium, and the process requirements. After calculation, it has been determined that a gearbox is needed that can provide approximately 500 N · m torque and a speed between 30-60 rpm. We ultimately chose the K107 gearbox and adopted a horizontal installation method. In actual operation, the reducer performs excellently with good mixing effect, providing strong guarantee for the stable operation of the sewage treatment plant.

1、 Application scenarios of K107 reducer in sewage treatment equipment

1. Mixing device

In the biochemical reaction tank of sewage treatment, it is necessary to stir the sewage to fully contact with microorganisms and promote the reaction. K107

The reducer can provide suitable speed and torque for the mixer, ensuring even mixing. For example, in an anaerobic reaction tank of a large urban sewage treatment plant, K107

The mixing device driven by a reducer can fully mix sludge and sewage, improve reaction efficiency, and accelerate the decomposition of organic matter.

2. Sludge reflux pump

Return the settled sludge to the front-end treatment unit to maintain the microbial concentration in the biological treatment system. K107

The reducer can provide stable power for the sludge reflux pump, ensuring its normal operation under different working conditions. At a sewage treatment plant in an industrial park, K107

The reducer effectively drives the sludge reflux pump, ensuring the stability and efficiency of the treatment process.

3. Decanter

In the sequencing batch reactor (SBR) process, a decanter is used to discharge the treated supernatant. The K107 reducer can accurately control the action of the decanter, achieving a smooth and efficient drainage process. For example, in an adoption

The K107 reducer ensures the accurate operation of the decanter and improves the effluent quality in a medium-sized wastewater treatment plant using SBR technology.

2、 Key points for selecting K107 reducer in sewage treatment equipment

1. Torque and speed requirements

Calculate the required torque and speed based on the process requirements and load characteristics of the processing equipment. For example, for large mixing devices, a large torque is required to overcome resistance; For the decanter, more attention may be paid to precise control of the rotational speed. In a sewage treatment plant with a large daily processing capacity, a detailed analysis of the agitator load was conducted to select one with sufficient torque output

K107 gearbox.

2. Working environment

Consider harsh environmental conditions such as humidity and corrosive gases in sewage treatment plants. Choose K107 with good protection level and corrosion resistance performance

Gearbox model. In a coastal sewage treatment plant, due to the high salt content in the air, K107 reducers that have undergone special anti-corrosion treatment were selected to prevent corrosion damage.