Advantages of MVS060L2 planetary reducer structure and materials

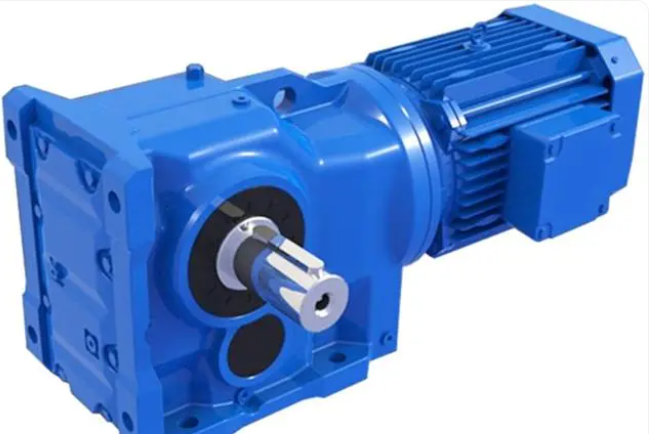

The MVS060L2 planetary gearbox, with its unique structure and high-quality materials, has demonstrated many significant advantages in the field of transmission.

From a structural perspective, MVS060L2 adopts a planetary gear transmission structure. The core advantage of this structure lies in its design of multiple planetary gears, which are evenly distributed around the sun gear to share the load. This enables the load to be more evenly distributed on each gear, greatly improving the load-bearing capacity of the gearbox. For example, in heavy-duty industrial equipment, even in the face of momentary high load shocks, this structure can easily cope and ensure the stable operation of the equipment.

In addition, the planetary gear transmission structure also achieves a compact design. Compared to traditional reducers, MVS060L2 has a smaller volume and occupies less space at the same output torque. This provides greater flexibility for the overall layout and installation of equipment, especially in space constrained application scenarios such as inside precision instruments or small automated devices.

In terms of materials, MVS060L2 also has excellent performance. Its gears are usually made of high-strength alloy steel, which has undergone precise heat treatment and possesses excellent hardness and wear resistance. This enables the gears to maintain good tooth profile accuracy and transmission performance even under long-term high load operation, extending the service life of the gearbox.

For example, in a continuously running production line, high-strength gear materials can withstand long-term wear and tear, reducing downtime for maintenance caused by gear damage and improving production efficiency.

Meanwhile, the casing and shaft components of the gearbox are generally made of high-quality cast iron or aluminum alloy materials. Cast iron has good rigidity and shock absorption properties, which can effectively absorb vibrations and impacts during transmission and reduce noise; Aluminum alloy has a lighter weight and good thermal conductivity, which helps with heat dissipation and improves the stability of the gearbox.

In addition, high-quality specialized bearing steel is used for the internal rolling bearings, ensuring high precision and low friction of the rotating components, further improving transmission efficiency and reliability.

In summary, the MVS060L2 planetary gearbox, with its advanced structural design and high-quality material selection, has demonstrated significant advantages in load-bearing capacity, space utilization, wear resistance, stability, and provides efficient and reliable transmission solutions for various industrial applications.