How to add reducer lubricating oil

As an important component of mechanical equipment, the method of adding lubricating oil to the gearbox has a crucial impact on its normal operation and service life. This article will provide a detailed introduction to the method of adding lubricating oil to the gearbox, helping users maintain the gearbox correctly.

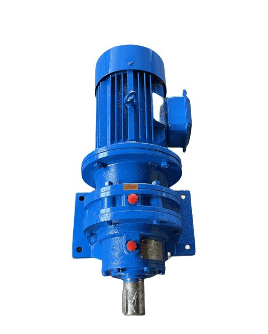

Image

1、 The role of gearbox lubricating oil

The main function of gearbox lubricating oil is to reduce friction and wear, while also having cooling, rust prevention, cleaning and other functions. Lubricating oil can form an oil film, separating two friction surfaces and reducing friction and wear. In addition, lubricating oil can also take away the heat generated by friction, playing a cooling role. In some cases, lubricating oil can also prevent metal surface oxidation and corrosion, maintaining the good condition of the equipment.

2、 Timing of adding lubricating oil to the gearbox

Regular addition: Based on the usage and working conditions of the reducer, develop a reasonable plan for regularly adding lubricating oil. Generally speaking, for continuously running gearboxes, lubricating oil needs to be added every 3-6 months. For intermittent reducers, the addition cycle can be appropriately extended or shortened based on actual operating time and workload.

Observation method: By observing the operation of the gearbox and the state of the lubricating oil, determine whether lubricating oil needs to be added. If abnormal sound, high temperature, darkened lubricating oil color, or impurities are found during the operation of the reducer, lubricating oil should be added in a timely manner.

Oil level method: Determine whether lubricating oil needs to be added by observing the gearbox oil level indicator or oil dipstick. When the oil level is below the minimum oil level line, lubricating oil should be replenished in a timely manner.

3、 The method of adding lubricating oil to the gearbox

Direct drip addition: For small reducers or local lubrication situations, drip addition can be used to supplement lubricating oil. Add lubricating oil droplets into the oil filling hole or oil cup until the oil level meets the requirements.

Oil gun oiling: For large reducers or centralized lubrication systems, an oil gun can be used for oiling. Insert the oil gun into the lubricating oil barrel and guide the lubricating oil to the oil filling port of the reducer using an oil delivery pipe until the oil level meets the requirements.

Pressure oil injection: For gearboxes that require quick replenishment of a large amount of lubricating oil, pressure oil injection can be used. Inject lubricating oil into the oil chamber of the reducer through pressure to ensure uniform distribution and sufficient filling of lubricating oil.

4、 Precautions for gearbox lubricating oil

Choose appropriate lubricating oil: Choose the appropriate lubricating oil based on the model, working conditions, and load situation of the reducer to avoid using unsuitable lubricating oil that may cause damage to the reducer.

Control the temperature of lubricating oil: During the operation of the reducer, the temperature of lubricating oil should be controlled to avoid excessive or insufficient temperature affecting lubrication effectiveness and service life.

Keep clean: During use, keep the gearbox oil tank and lubricating oil clean to prevent debris and moisture from entering the lubrication system.

Regularly replace lubricating oil: Replace lubricating oil regularly according to the actual situation, and it is generally recommended to replace it every 3-6 months. When replacing, pay attention to cleaning and inspecting the internal parts of the gearbox.

Attention to safety: During the process of adding lubricating oil, attention should be paid to safety to avoid lubricating oil splashing onto sensitive areas such as skin or eyes. At the same time, attention should also be paid to fire safety and avoidance.