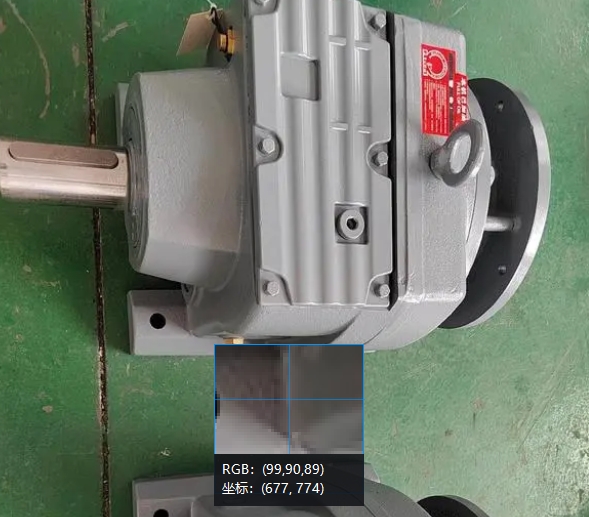

Wear resistant helical gear reducer R87-Y2.2-4P-42.5-270 foot shaft extension installation

The wear-resistant helical gear reducer R87-Y2.2-4P-42.5-270 foot shaft extension installation is a high-quality reducer with wear resistance and reliability, suitable for various industrial fields. This article will provide a detailed introduction to the characteristics, installation steps, and maintenance of this reducer, providing you with a comprehensive understanding.

This wear-resistant helical gear reducer is manufactured using advanced technology and materials, with high strength and wear resistance. It adopts the principle of helical gear transmission, which can achieve high torque output and smooth operation. At the same time, the foot shaft extension installation design of the reducer makes it easier to install and maintain.

When installing this reducer, it is necessary to prepare the installation position and related tools first. Firstly, clean the installation location to ensure it is flat and clean. Then, place the reducer in the appropriate position and secure it with bolts. During installation, attention should be paid to connecting the reducer to other equipment to ensure its stability and flexibility.

After the installation of the gearbox is completed, a series of operational tests and debugging work need to be carried out. Firstly, check if the transmission part is installed correctly and add lubricating oil. Then, through no-load operation and load operation testing, ensure that the gearbox operates normally and stably. During the testing process, it is necessary to pay attention to indicators such as operating temperature, noise, and vibration. If there are any abnormal situations, they need to be dealt with in a timely manner.

In order to ensure the long-term stable operation of the gearbox, regular maintenance and upkeep are also necessary. Firstly, regularly replace the lubricating oil to ensure its service life and performance. At the same time, clean the gearbox to remove dust and impurities. Regularly inspect and maintain the gear teeth and bearings to ensure their normal operation.