Exquisite manufacturing process of MPVB090AL1 planetary reducer

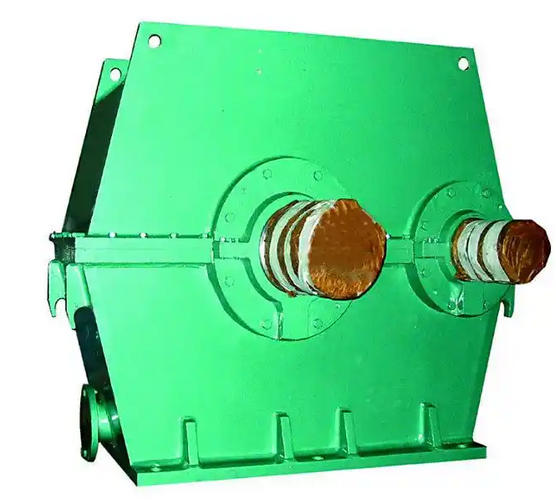

In the modern industrial field, high-performance transmission equipment is crucial for improving production efficiency and product quality. MPVB090AL1 planetary gearbox has become the preferred choice for many industries due to its exquisite manufacturing process.

1、 High precision machining

In the manufacturing process of MPVB090AL1 planetary gearbox, high-precision machining is one of the key links. Using advanced CNC machining equipment, precision machining is carried out on key components such as gears, shafts, and casings to ensure extremely high standards of dimensional accuracy and form and position tolerances. For example, the machining accuracy of gears can reach the micrometer level, ensuring the smoothness and accuracy of gear meshing, thereby improving the transmission efficiency and accuracy of the reducer.

2、 High quality material selection

In order to ensure the performance and reliability of the gearbox, MPVB090AL1 planetary gearbox selects high-quality materials. Gears are usually made of high-strength alloy steel and undergo heat treatment processes such as quenching and tempering to improve their hardness and wear resistance. The box is made of high-strength cast iron or aluminum alloy, which has good rigidity and corrosion resistance. At the same time, high-quality bearings, seals, and other accessories are selected to ensure the overall performance of the gearbox.

3、 Strict quality control

Strict quality control is essential in the manufacturing process to ensure

MPVB090AL1 planetary gearbox is an important means of quality assurance. Strict quality control is carried out at every stage, from raw material inspection to dimensional testing, hardness testing, and non-destructive testing during the processing. At the same time, comprehensive performance testing is conducted on the finished reducer, including transmission efficiency testing, noise testing, temperature rise testing, etc., to ensure that each reducer meets high-quality standards.

4、 Advanced assembly technology

The assembly process of MPVB090AL1 planetary gearbox adopts advanced technology and equipment. Assembly workers undergo professional training and strictly follow the assembly process requirements for operation. During the assembly process, precision measuring tools and equipment are used to ensure the installation accuracy of each component. At the same time, debug and break in the assembled reducer to ensure its optimal performance.

5、 Surface treatment

In order to improve the appearance quality and corrosion resistance of the gearbox, MPVB090AL1 planetary gearbox has undergone fine surface treatment. The box body is usually treated with spray paint or plastic coating, while components such as gears and shafts are treated with electroplating or blackening. These surface treatment processes not only improve the aesthetics of the gearbox, but also extend its service life.

In short, the exquisite manufacturing process of MPVB090AL1 planetary gearbox reflects the high level of modern industry. Through high-precision machining, high-quality material selection, strict quality control, advanced assembly technology, and surface treatment, the high performance, high reliability, and long service life of the reducer are ensured, providing strong support for the development of various industries.