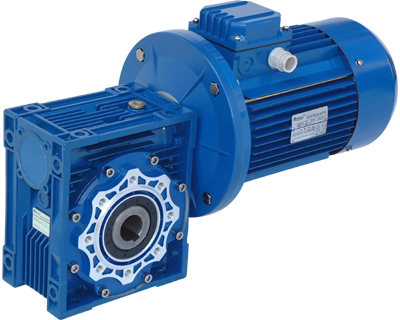

Syrup filling production line WPA worm gear reducer

The syrup filling production line WPA worm gear reducer is suitable for bottle filling production lines in industries such as pharmaceuticals, food, and chemicals. It meets the requirements of the new GMP standards and can complete automatic bottle sorting, aluminum foil sealing, labeling, and other processes. The entire production line occupies a small area, operates stably, and is economical and practical.

Among them, the WPA worm gear reducer in the syrup filling production line uses a conveyor type bottle loading machine, which saves manpower and has higher efficiency. Clean the bottles with purified gas on the machine. Ensure the cleanliness of the bottles and equip them with an electrostatic decontamination ion air bar device. The plunger metering pump performs filling, using various viscous liquids with high accuracy; The structure of the pump adopts a quick connect disassembly mechanism, which is easy to clean and disinfect. The piston ring material of the plunger metering pump is made of silicone rubber, tetrafluoroethylene, or other materials according to the industry and liquid composition. In special occasions, ceramic materials are used!

WPA worm gear reducer for syrup filling production line, PLC control J system for the entire line, variable frequency speed regulation, high degree of automation, convenient filling adjustment, and can adjust the filling amount of all measuring pumps at once. It can also be slightly adjusted for each measuring pump; Easy to operate and quick to adjust. The filling needle is designed with an anti drip device. It can be filled by diving into the bottom of the bottle and slowly rising to prevent foaming. Rotary continuous bottle feeding, operating mechanism, stable, reliable, high-speed operation, and the entire line can be designed according to GMP requirements.