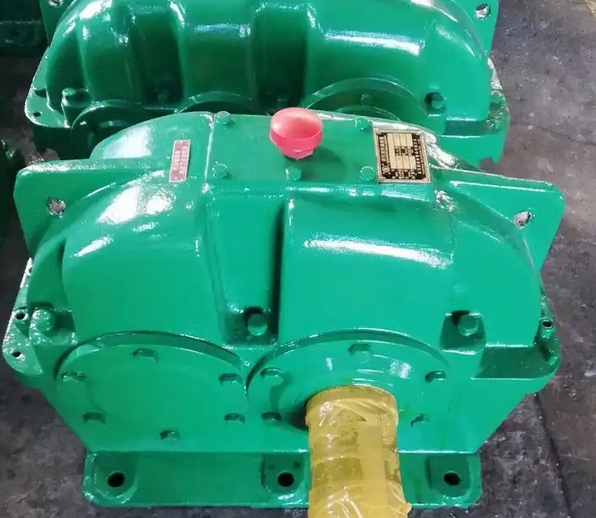

Detailed guide to the installation method of BWD5 reducer reduction motor BWD5-47-18.5

The BWD5 reducer and reduction motor is a common mechanical equipment widely used in various industrial fields. This article will provide you with a detailed guide for installing the BWD5-47-18.5 reduction motor, helping you complete the installation process correctly and efficiently.

Firstly, let's learn about the basic information of the BWD5-47-18.5 reduction motor. The reduction motor adopts the BWD5 reducer model, with a reduction ratio of 47 times. Its power is 18.5 kilowatts, suitable for some larger equipment and machinery. Before installation, you need to ensure that the model of the reduction motor matches the requirements of your equipment.

Next, let's take a step-by-step look at the installation method of the BWD5-47-18.5 reduction motor. Firstly, you need to choose a suitable installation location. Usually, it is recommended to choose a place closer to the power source and with good air circulation. At the same time, it is also necessary to consider the operating environment of the deceleration motor and avoid places that are too humid or dusty.

After determining the installation location, you need to carry out a series of installation preparations. Firstly, check the appearance of the deceleration motor to ensure that there is no obvious damage or deformation. Then, clean the installation position to ensure that there are no debris or dust affecting the installation. In addition, it is necessary to prepare the necessary installation tools and materials, such as screwdrivers, wrenches, brackets, etc.

Next, we will begin the specific installation steps. Firstly, bring the reduction motor closer to the installation position and secure it in a suitable position using a bracket. Ensure that the bracket is sturdy and reliable, able to withstand the weight of the deceleration motor. Then, use a screwdriver and wrench to connect the reduction motor to the bracket, ensuring a secure connection.

After installation, a series of debugging and testing are required. Firstly, check if the connection between the deceleration motor and other equipment is secure to ensure that there is no looseness or detachment. Then, turn on the power and observe the operating status of the deceleration motor. If everything is normal, the deceleration motor should be able to run smoothly without any abnormal sounds or vibrations.

Finally, regular maintenance and upkeep work is required to ensure the long-term normal operation of the BWD5-47-18.5 reduction motor. Regularly clean the appearance of the deceleration motor and check if the power circuit and connecting components are normal. If any abnormal situations are found, they should be dealt with and repaired in a timely manner to avoid affecting the service life of the deceleration motor.