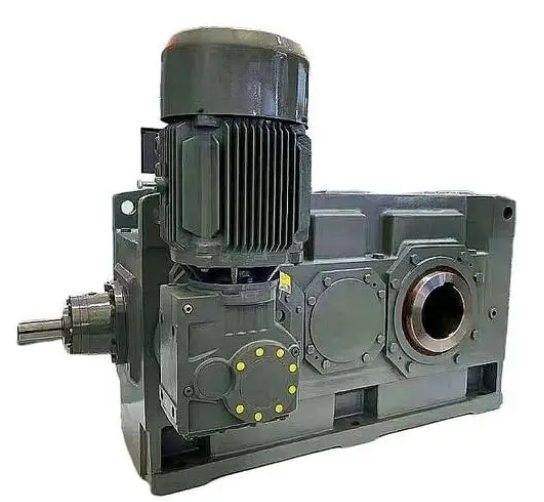

B series gearbox B4SH07 brand new hard tooth surface reducer excellent workmanship

In the vast field of industrial automation and mechanical manufacturing, the B-series gearbox has won widespread recognition and favor in the market for its excellent performance and stable quality. Among them, B4SH07 hard tooth surface reducer, as a leader in this series, has shone in many industrial applications due to its excellent workmanship, efficient transmission efficiency, and strong load-bearing capacity. This article will deeply analyze the unique charm of B4SH07 hard tooth reducer from four aspects: design concept, manufacturing process, performance characteristics, and application examples.

###Design philosophy: precise positioning, pursuit of excellence

At the beginning of the design of B4SH07 hard tooth reducer, the core concept of "precise positioning and pursuit of excellence" was clearly defined. The design team fully considered the higher requirements of modern industry for reducers, such as higher transmission efficiency, lower noise levels, stronger impact resistance, and longer service life. By adopting advanced CAD/CAM assisted design technology and combining years of industry experience, B4SH07 has achieved optimization and innovation in structural design, ensuring that every detail can reach the best state.

###Manufacturing Process: Striving for Excellence, Craftsmanship

Manufacturing process is the cornerstone of product quality. The B4SH07 hard tooth reducer strictly follows the ISO9001 quality management system standard in the production process. From raw material procurement to finished product delivery, every process undergoes strict quality control and testing. As the core component of the gearbox, gears are made of high-strength alloy steel materials and processed through multiple processes such as precision forging, heat treatment, and precision grinding, ensuring that the hardness, wear resistance, and accuracy of the gears reach industry-leading levels. At the same time, the box is made of high-quality cast iron or cast steel material, which has undergone aging treatment to effectively eliminate internal stress and improve overall rigidity and stability.

###Performance characteristics: efficient, stable, reliable and durable

The B4SH07 hard tooth reducer stands out among many similar products due to its unique performance characteristics. Firstly, its transmission efficiency is over 95%, effectively reducing energy consumption and improving the working efficiency of the equipment. Secondly, the use of high-precision bearings and sealing devices effectively reduces operating noise and oil leakage, ensuring a clean and quiet working environment. Furthermore, the hard tooth surface design significantly enhances the load-bearing capacity of the gear pair, ensuring stable transmission performance even under heavy loads or high-speed operating conditions. In addition, B4SH07 also has good thermal balance performance, which can effectively control temperature rise and extend service life even under long-term continuous operation.

###Application example: Widely applicable, highlighting value

The B4SH07 hard tooth reducer plays an important role in multiple industries due to its excellent performance and wide range of applications. In the metallurgical industry, it is widely used in the transmission system of heavy equipment such as rolling mills and continuous casting machines, effectively improving the stability and efficiency of production lines;