Planetary reducer or hard tooth surface reducer, which one is more cost-effective?

In modern mechanical equipment, reducers play a crucial role. As a core component of the transmission device, the reducer can convert the high-speed rotating input shaft into a low-speed and high torque output shaft, providing stable power output for the equipment. In the field of reducers, planetary reducers and hard tooth reducers are very common and widely used options. So, which type of reducer has a higher cost-effectiveness? Let's explore it!

A planetary gearbox is a type of reducer that operates on the principle of planetary gears. It consists of a sun gear, a planetary gear, an internal gear, and an external gear. During the work process, the sun gear drives the planetary gear to rotate, and the planetary gears on the planetary gear rotate around the internal gear simultaneously, thereby achieving a deceleration effect. Planetary reducers have advantages such as compact structure, large load-bearing capacity, and stable transmission. Meanwhile, due to the use of multi tooth docking, the working noise of the planetary reducer is relatively low. This makes planetary reducers particularly suitable for situations that require noise in the working environment, such as mechanical manufacturing, electric power transmission, and other fields.

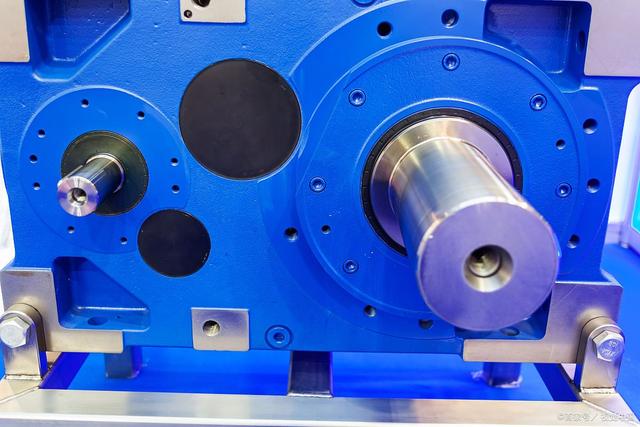

On the contrary, it is a hard tooth surface reducer, which adopts the principle of hard tooth surface transmission. The hard tooth reducer mainly consists of an input shaft, an output shaft, multiple intermediate shafts, and corresponding gears on them. Due to the use of hard tooth surface transmission, the hard tooth surface reducer has the characteristics of high transmission efficiency and strong load-bearing capacity. At the same time, the hard tooth reducer also has advantages such as simple structure, high accuracy, and long service life. Therefore, hard tooth reducers have been widely used in many high load, high-speed transmission systems, such as steel, mining, shipbuilding and other fields.

So, how to choose between a planetary gearbox and a hard tooth surface gearbox? The first thing to consider is the specific application scenario and requirements. If there is a high demand for noise, limited space, and large transmission ratio, a planetary reducer is a better choice. For high load and high speed transmission systems, hard tooth surface reducers have more advantages.

In addition, cost factors also need to be considered. Planetary reducers are relatively complex in structure and require high manufacturing processes, therefore their prices are relatively high. The hard tooth reducer is relatively simple and has a relatively low manufacturing cost. In the case of limited budget, a hard tooth reducer can become a more cost-effective choice.

In summary, planetary reducers and hard tooth reducers each have their own characteristics and different adaptability in different application scenarios. From the perspective of cost-effectiveness, it is necessary to make choices based on specific needs and budget. Whether it is a planetary gearbox or a hard tooth reducer, the maximum performance can only be achieved by selecting the appropriate product and using it correctly.