Model and characteristics of RV20/RV20E robotic arm joint reducer

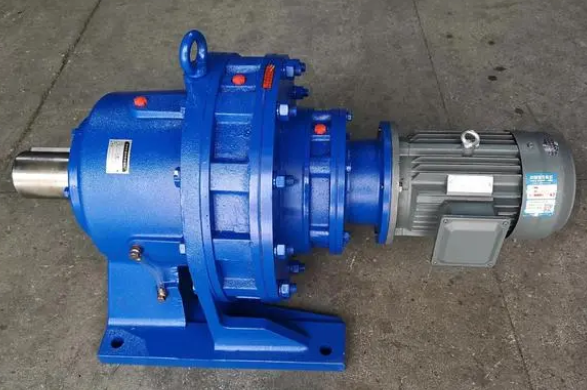

The working principle of the RV joint reducer is a high-precision control reducer using a cycloidal pinwheel reduction structure, which can achieve good acceleration performance, smooth operation, and correct position accuracy. It is a two-stage reduction mechanism composed of involute planetary gear transmission and cycloid needle wheel transmission, belonging to a crank type closed differential gear system, with the structural characteristics of parallel structure and multi tooth meshing constraint.

The RV joint reducer models are as follows. There are differences in the representation of different manufacturers' models. Please consult customer service for specific models

Characteristics of RV-E series reducer

1. The transmission ratio range is large.

2. High torsional stiffness. The output mechanism is a planetary carrier supported at both ends, and its torsional stiffness is much higher than that of the output mechanism of a general cycloidal pinwheel planetary gearbox. At rated torque, the elastic hysteresis is small.

When the design is reasonable and the manufacturing and assembly accuracy are guaranteed, high precision and small gap backlash can be achieved.

4. High transmission efficiency.

5. Small size and light weight. Due to the first stage being planetary gear transmission and the second stage being cycloidal pinwheel multi tooth meshing transmission, the transmission mechanism can be placed inside the supporting bearings of the planetary carrier, resulting in a significant reduction in axial size and volume.

Application scenarios of RV joint reducer:

Industrial robot: RV joint reducer is a key component in industrial robots, used for precise control of robot joint motion.

Numerical control machine tools: equipment that requires precise transmission and positioning often uses harmonic reducers.

Aerospace and military industries: Due to their high requirements for accuracy and reliability, robot reducers are also commonly used in these fields.

Medical equipment: It is also applied in medical devices that require precise control and high reliability.

RV-20E、 Precautions for assembling input gears

The RV-20E has 2 planetary gears, please pay special attention when assembling the input gears. The input gear should be inserted directly.

When the phase of the planetary gear does not match, please insert it at a slightly different angle along the circumference, and ensure that the motor flange surface is not tilted and in close contact. It is strictly prohibited to use bolts or other tools to screw in. If the flange surface is tilted, it may cause the state shown in Figure 12 on the left. If the flange surface is not tilted, it may cause the state shown in Figure 13 on the right.