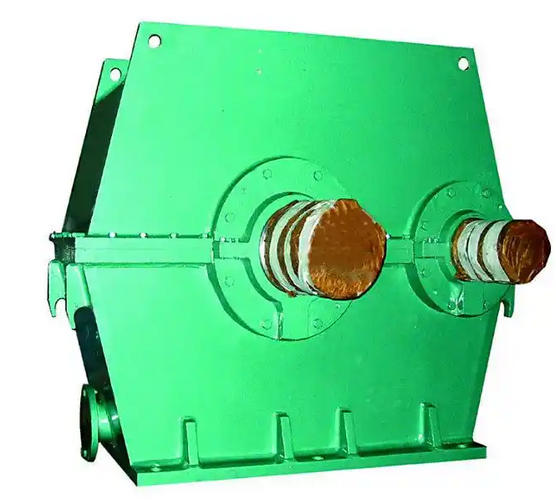

XWED63-289-0.55KW reducer BLED20-289-0.37KW reducer hard tooth surface

In the fields of mechanical manufacturing and industrial automation, the performance and reliability of the gearbox, as a key transmission equipment, play a crucial role in the smooth operation of the entire production line. This article will take the XWED63-289-0.55KW reducer and BLED20-289-0.37KW reducer as examples to explore in depth the technical characteristics, application areas, and maintenance of hard tooth surface reducers.

1、 Technical characteristics of hard tooth surface reducer

Hard tooth surface reducers occupy an important position in the field of modern industrial transmission due to their significant characteristics such as high load-bearing capacity, high efficiency, and long service life. The XWED63-289-0.55KW reducer and BLED20-289-0.37KW reducer, as typical representatives of hard tooth surface reducers, adopt advanced heat treatment technology and precision machining processes to ensure the hardness and wear resistance of gear tooth surfaces. At the same time, they also use high-strength materials and optimized structural design, allowing the gearbox to withstand greater torque and impact forces, ensuring the stable operation of the transmission system.

2、 Application fields of hard tooth surface reducer

Hard tooth surface reducers are widely used in transmission systems in industries such as metallurgy, mining, chemical, cement, construction, textile, papermaking, and printing. They can be used to drive various mechanical equipment, such as fans, pumps, compressors, mixers, etc., to achieve functions such as deceleration, torque increase, and speed change. In industrial production, the high efficiency and long service life characteristics of hard tooth surface reducers can greatly reduce equipment failure rates and maintenance costs, improve production efficiency and economic benefits.

3、 Performance Comparison between XWED63-289-0.55KW Reducer and BLED20-289-0.37KW Reducer

There are differences in power, speed ratio, and installation size between XWED63-289-0.55KW reducer and BLED20-289-0.37KW reducer. The XWED63-289-0.55KW reducer has high power and a wide speed ratio range, making it suitable for applications that require heavy loads and high speeds. The BLED20-289-0.37KW reducer has a smaller installation size and lower power, making it suitable for situations with limited space and low loads. In practical applications, users can choose the appropriate reducer model based on specific working conditions and needs.

4、 Maintenance and upkeep of hardened gear reducers

In order to ensure the normal operation and prolong the service life of the hard tooth surface reducer, users need to regularly maintain and upkeep the reducer. Firstly, it is necessary to regularly check the oil level and quality of the gearbox to ensure that the cleanliness and viscosity of the lubricating oil meet the requirements. Secondly, it is necessary to check whether the fasteners of the gearbox are loose or damaged, and promptly tighten or replace them. In addition, it is necessary to check the wear of key components such as gears and bearings of the reducer, and replace or repair them according to the actual situation. Finally, it is necessary to regularly clean and lubricate the gearbox to maintain its cleanliness and lubrication status.