Basic functions and working principles of planetary reducer

Planetary reducer is a widely used transmission device in the industrial field, characterized by high reduction ratio, high efficiency, high precision, and long service life. It can reduce the input high-speed rotational motion to a lower speed and increase the output torque, meeting the requirements of various mechanical equipment for deceleration transmission.

The basic function of a planetary reducer is to achieve deceleration transmission. It transmits the high-speed rotational motion of the input to the output shaft through the meshing of the planetary gears, achieving the purpose of deceleration. At the same time, planetary reducers also have the functions of withstanding large torques, improving mechanical efficiency, reducing noise and vibration, etc. In various industrial fields, planetary reducers are widely used in textile, packaging, printing, electronic product manufacturing, robotics, medical equipment and other fields.

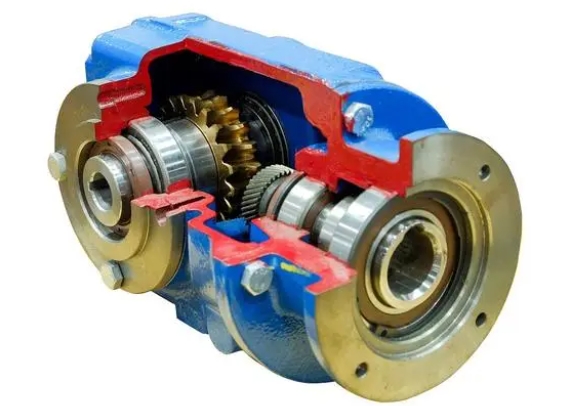

The working principle of planetary reducer is based on the meshing transmission of planetary gears. The number of planetary gears is generally three or more, and these planetary gears rotate under the drive of the sun gear, while also rotating with the inner ring gear and planetary carrier. Through the meshing transmission of planetary gears, the input high-speed rotational motion is converted into lower speeds and larger torques, and output to the planetary carrier. During the operation of the planetary reducer, various components cooperate with each other to achieve high reduction ratio and high efficiency transmission.

In order to better understand the working principle of planetary reducers, we need to understand their internal structure and working process. The internal structure of the planetary reducer mainly includes the input shaft, sun gear, planetary gear, inner ring gear, and planetary carrier. During the working process, the input shaft drives the sun gear to rotate, and the planetary gear undergoes revolution and rotation under the joint action of the sun gear and the inner ring gear, transmitting power to the planetary carrier and achieving deceleration transmission.

In addition to its basic structure and functions, planetary reducers also have many advantages. Firstly, it has high reduction ratio and high efficiency, which can meet the requirements of various mechanical equipment for reduction transmission. Secondly, the design of planetary reducers is compact, small in size, lightweight, and easy to install and maintain. In addition, the planetary reducer has smooth transmission, low noise, and long service life, which can ensure long-term stable operation. Finally, planetary reducers have strong adaptability and can be customized according to different work requirements, widely used in various industrial fields.

In order to fully leverage the advantages of planetary reducers, it is necessary to use and maintain them correctly. During use, it should be ensured that the input shaft speed does not exceed the rated value to avoid overloading and damage to the gearbox. At the same time, regular lubrication checks should be carried out to ensure the normal operation of all components. During the maintenance process, vulnerable parts should be cleaned and replaced according to the actual situation to ensure the long-term stable operation of the planetary reducer.

In summary, planetary reducers, as an important transmission device, have broad application prospects. Understanding its basic functions and working principles helps to better use and maintain planetary reducers, improve the efficiency and service life of mechanical equipment. With the continuous development of industrial technology, the performance and application range of planetary reducers will also continue to expand and innovate.