How to choose a planetary gearbox suitable for the automation field

In the field of automation, planetary gearbox is an important transmission device that has a critical impact on the performance and accuracy of the system. Here is an example to illustrate in detail how to choose a suitable planetary gearbox.

In the field of automation, planetary gearbox is an important transmission device that has a critical impact on the performance and accuracy of the system. Here is an example to illustrate in detail how to choose a suitable planetary gearbox.

Assuming we have an automated production line project, we need to choose a planetary gearbox to drive a conveyor belt.

Firstly, we need to clarify the load situation of the conveyor belt. Including the total weight of the conveyor belt and the objects carried on it, as well as the maximum impact force that may be generated during operation. This will determine the amount of torque that the gearbox needs to withstand.

Secondly, consider the speed requirements. The conveyor belt needs to run at a specific speed, and we need to determine the input and output speeds of the reducer based on this requirement.

Next, evaluate the accuracy requirements. If the precision requirements for the operation of the conveyor belt are high, it is necessary to choose a planetary reducer with high precision to ensure smooth and accurate transmission.

When making specific choices, the following are some key points:

Reduction ratio: Calculate the appropriate reduction ratio based on the input speed and expected output speed. For example, if the input speed is 1400 revolutions per minute and the expected output speed is 70 revolutions per minute, then the reduction ratio is approximately 20.

Torque capacity: Ensure that the selected planetary gearbox can withstand the maximum torque generated by the conveyor belt. Generally, a certain safety margin should be left to cope with possible overload situations.

Size and installation method: Based on the spatial layout and installation conditions of the equipment, select the appropriate size and installation method of the reducer to ensure that it can be easily installed in the designated position.

Brand and Quality: Choose a well-known and reputable planetary gearbox to ensure better quality and reliability.

Working environment: Consider factors such as temperature, humidity, and dust in the working environment of the gearbox. If the environment is harsh, it is necessary to choose a gearbox with the corresponding protection level.

Noise level: For some noise sensitive application scenarios, it is necessary to choose a planetary gearbox with lower operating noise.

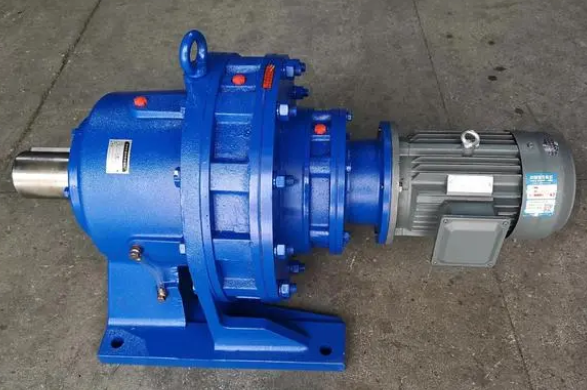

Based on the above considerations, we may choose a well-known brand planetary gearbox with a suitable reduction ratio, sufficient torque capacity, compact size, easy installation, and adaptability to the working environment. For example, [specific brand and model] planetary gearbox, which has the following characteristics:

The reduction ratio meets our requirements, and the torque capacity can easily cope with the load of the conveyor belt; Compact size, not taking up too much space, flexible and convenient installation method; Adopting high-quality materials and manufacturing processes, with good reliability and durability; Can adapt to the working environment temperature and humidity of our production line, and operate with low noise.