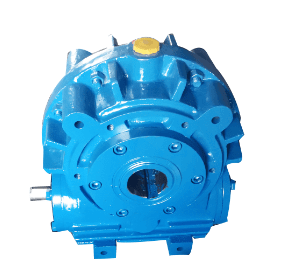

What are the output shaft forms of the RV series worm gear reducer

The output shaft forms of the RV series worm gear reducer mainly include the following types

:

Hole output: The output end is a hole that can be connected to other components by installing keys, pins, and other parts inside the hole. It is suitable for situations where the motion of the output shaft needs to be transmitted to shaft parts that are matched with it, such as connecting to other shafts through couplings or installing transmission components such as gears and pulleys inside the hole.

Unidirectional shaft output: A solid shaft that extends in only one direction and can transmit power in one direction. Various transmission components such as sprockets, pulleys, gears, etc. can be installed at the shaft end to drive other devices or mechanisms. It is a common form of output and widely used in various devices that require unidirectional power output.

Bidirectional shaft output: With shafts extending in opposite directions, power can be transmitted in both directions simultaneously. It is suitable for situations where other components need to be driven in two different positions or directions, such as simultaneously driving conveyor belts on both sides or connecting different transmission devices in different directions. It can effectively save space and simplify the transmission structure.

Flange output: Connected output is achieved through a flange plate, which has evenly distributed bolt holes. The installation surface of the reducer can be tightly connected to other equipment using bolts, with the characteristics of stable connection, high torque transmission, and high installation accuracy. It is commonly used in situations where high installation accuracy and stability are required, such as in some large mechanical equipment or automated production lines that require high-precision transmission.