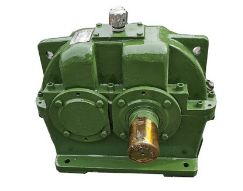

Comparison of gear reducer and screw reducer

There are some differences in principle, structure, application, and efficiency between gear reducers and screw reducers, but there are also some similarities.

1、 Differences:

Transmission principle: Gear reducers transmit power through the meshing of gears, while screw reducers transmit power through the relative motion between screws and nuts.

Structure: The gear reducer mainly consists of an input shaft, gears, bearings, and a box, while the screw reducer mainly consists of screws, nuts, rolling bearings, and a box.

Application: Gear reducers are suitable for transmitting high power, high torque, and high-speed operation in fields such as mechanical equipment, transportation equipment, and industrial automation. Screw reducers are suitable for transmitting small and medium power, low torque, and low-speed operation, such as medical equipment, food machinery, and printing machinery.

Efficiency: Under the same conditions, the efficiency of gear reducers is generally higher than that of screw reducers. Because the transmission chain of the gear reducer is shorter and the energy loss is smaller, the efficiency is higher.

2、 Similarities:

Reduction ratio: Both gear reducers and screw reducers have higher reduction ratios, which can achieve greater torque transmission and speed reduction.

Stability: Both have good stability and can maintain stable transmission performance for a long time.

Maintenance: Both require regular maintenance to ensure their normal operation and extend their service life.

Application scope: Both have extensive applications in the field of mechanical transmission, and can be selected according to different needs.

In summary, there are differences between gear reducers and screw reducers in terms of principle, structure, application, and efficiency, but there are also similarities in terms of reduction ratio, stability, and maintenance. In practical applications, suitable types of reducers can be selected according to specific needs.