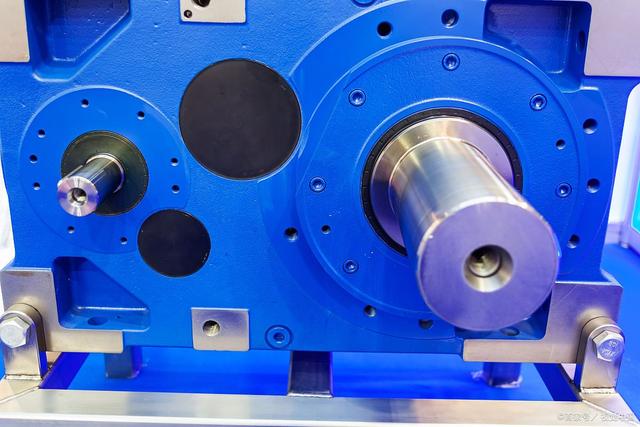

The difference and application between hard tooth surface reducer and ordinary reducer

1、 Introduction to Hard Gear Reducer and Ordinary Reducer

In the field of mechanical transmission, there are many types of reducers, among which hard tooth surface reducers and ordinary reducers are two common ones. They have significant differences in structure, performance, and application. Different characteristics have different uses. Next, we will discuss the differences between hard tooth surface reducers and ordinary reducers and their applications in different fields.

2、 The difference between hard tooth surface reducer and ordinary reducer

(1) Gear material and heat treatment

1. Hard tooth surface reducer

Adopting high-strength alloy steel and undergoing deep heat treatment processes such as carburizing and quenching, the tooth surface hardness is high and the bearing capacity is strong.

2. Ordinary gearbox

The gear material and heat treatment are relatively simple, with low hardness and load-bearing capacity.

(2) Transmission efficiency

1. Hard tooth surface reducer

The transmission efficiency is relatively high, generally reaching over 95%.

2. Ordinary gearbox

The transmission efficiency is usually around 90%.

(3) Service life

1. Hard tooth surface reducer

Due to the high hardness, good wear resistance, and long service life of gears.

2. Ordinary gearbox

Relatively short.

(4) Cost

1. Hard tooth surface reducer

The manufacturing process is complex and the cost is high.

2. Ordinary gearbox

Low cost.

3、 Application of Hard Gear Reducer and Ordinary Reducer

(1) Heavy load working condition

1. Hard tooth surface reducer

Such as mining machinery, lifting equipment, etc., can withstand large impacts and heavy loads.

For example, in large cranes, hard toothed reducers ensure stable operation and reliable transmission when lifting heavy objects.

2. Ordinary gearbox

Generally not applicable.

(2) High precision requirements

Hard tooth surface reducer

Can provide high transmission accuracy.

The transmission system of CNC machine tools, such as hard tooth surface reducers, ensures machining accuracy.

Ordinary gearbox

The accuracy is low and difficult to meet the requirements.

(3) Long term continuous operation

Hard tooth surface reducer

Suitable for long-term continuous work with good stability.

In large-scale factory assembly line equipment, hard tooth surface reducers can operate stably for a long time.

Ordinary gearbox

Frequent malfunctions may occur.