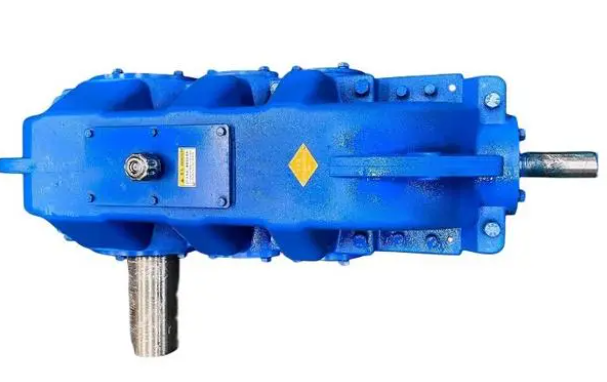

DCY280-40-1 series anti-seismic and high-temperature hardened surface reducer for converters in steel plants

In modern industrial production, reducers play a crucial role as key power transmission equipment. Especially in some special application scenarios, such as converters in steel production, equipment is required not only to withstand large loads, but also to have good shock resistance and high temperature resistance. The DCY280-40-1 series of seismic and high-temperature resistant hard tooth surface reducers used in steel mills' converters are ideal equipment designed for these needs. With their excellent performance and reliability, they have become an indispensable and important component of the steel industry. This article will explore in detail the technical specifications, working principles, advantages, and application areas of the DCY280-40-1 series reducer, in order to comprehensively interpret this high-end mechanical product.

1、 Technical specifications of DCY280-40-1 reducer

The DCY280-40-1 reducer belongs to the hard tooth surface reducer, and its main technical specifications have the following characteristics:

1. Output power: The rated output power range of DCY280-40-1 is wide, which can meet the needs of steel mills of different scales.

2. Transmission ratio: Its transmission ratio design is reasonable, which can achieve efficient power transmission and make the converter operation smoother.

3. Seismic performance: The reducer adopts advanced seismic design, which can effectively reduce vibration during high load operation and improve the service life of the reducer.

4. High temperature resistant materials: The key components inside the reducer are made of high temperature resistant materials, which can operate normally in environments with temperatures up to 300 ℃.

5. Sealing design: The DCY280-40-1 reducer adopts advanced sealing technology, which can effectively prevent dust and impurities from entering, ensuring the cleanliness and normal operation of the internal lubrication system.

2、 Working principle

The working principle of the DCY280-40-1 series reducer is relatively simple but very efficient. Its core components include input shaft, output shaft, and gear system. The motor transmits power to the reducer through the input shaft, and through an internal high-precision gear transmission system, it gradually decelerates to achieve high torque output. The design of hard tooth surfaces reduces the friction between gears and improves the efficiency of energy transmission.

In addition, in the high-temperature and high-pressure environment of the converter, the seismic design of the reducer and the application of high-temperature resistant materials ensure that the equipment can still operate stably under extreme working conditions. This consistency not only helps steel mills improve production efficiency, but also reduces equipment failure rates.

3、 Advantage analysis

1. Efficient and energy-saving

The design of DCY280-40-1 reducer fully considers energy efficiency and can achieve maximum output power with the lowest energy consumption. This is particularly important in the steel production process, reducing energy costs and enhancing overall sustainable development.

2. Durability

Due to its seismic and high-temperature resistance, the DCY280-40-1 series gearbox has extremely high durability. Whether in high temperature and high pressure environments or under continuous load, the service life of this equipment far exceeds that of similar products.