Factors affecting oil leakage of hard tooth surface reducer

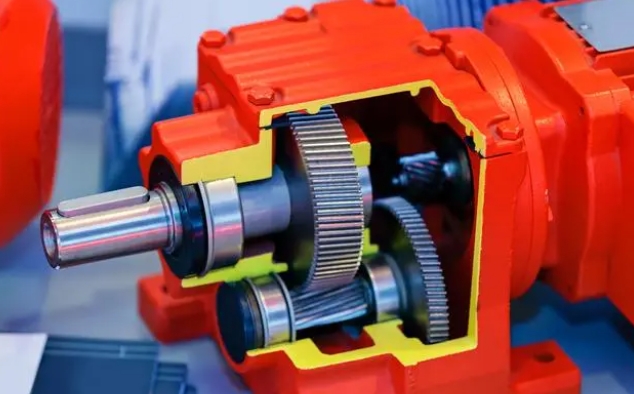

Hard tooth reducer, as a common industrial equipment, plays a very important role in industrial production. However, the problem of oil leakage in hard tooth reducers is a common and headache inducing problem. So, what are the influencing factors of oil leakage in hard tooth surface reducers? This article will provide you with a detailed analysis.

Firstly, the influencing factors of oil leakage in hard tooth surface reducers can be summarized as follows:

1. Sealing device failure: The sealing device of the hard tooth reducer is a key component to prevent oil leakage. If the sealing device is damaged, aged, or improperly installed, it can lead to oil leakage.

2. Hard tooth surface wear: During the operation of the hard tooth surface reducer, friction and wear will occur. If the wear is severe, it will lead to oil leakage. Common causes of wear include poor lubrication, excessive load, and high operating temperature.

3. Overloading: If the hard tooth reducer is subjected to a load that exceeds its designed carrying capacity for a long time during use, it will lead to oil leakage. Excessive loading can cause deformation and damage to the hard tooth surface, thereby affecting sealing performance and leading to oil leakage.

4. Poor quality of lubricating oil: The quality of lubricating oil can also have an impact on the oil leakage of hard tooth surface reducers. If the viscosity of lubricating oil is too high or too low, it is easy to cause oil leakage. At the same time, the cleanliness of lubricating oil and the type and concentration of additives can also affect the sealing performance of hard tooth surface reducers.

5. Improper installation: The installation quality of the hard tooth reducer also has a certain impact on oil leakage issues. If installed improperly, such as insufficient tightening of bolts or excessive side clearance, it may lead to poor sealing, which can cause oil leakage.

Through the analysis of the above factors, we can come up with some methods to prevent oil leakage in hard tooth surface reducers:

1. Regular inspection and replacement of sealing devices: Sealing devices are the first line of defense to reduce the risk of oil leakage, and regular inspection and maintenance of the integrity and rationality of sealing devices are very important.

2. Proper lubrication work: Reasonably select lubricating oil, pay attention to the addition and replacement cycle of lubricating oil, and ensure that the quality and quantity of lubricating oil meet the requirements.

3. Control load and working temperature: Reasonably control the load and working temperature of the hard tooth reducer to avoid excessive loading causing wear and oil leakage on the hard tooth surface.

4. Pay attention to installation quality: When installing the hard tooth reducer, pay attention to details to ensure firm installation and reasonable side clearance, to ensure its normal operation and sealing performance.

In summary, the influencing factors of oil leakage in hard tooth surface reducers include sealing device failure, hard tooth surface wear, excessive loading, poor lubricating oil quality, and improper installation. By regularly inspecting and maintaining the sealing device, doing a good job in lubrication, controlling the load and working temperature, and paying attention to installation quality, the occurrence of oil leakage problems in hard tooth surface reducers can be effectively reduced, and their service life can be extended.