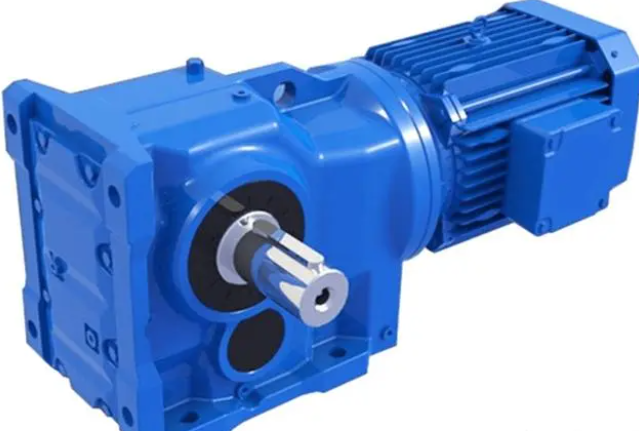

K series helical gear spiral bevel gear reduction motor

The umbrella gear helical gear reduction motor adopts a direct motor connection form, with a structure of one stage helical gear and one stage worm gear transmission. The output is shaft mounted and has six basic installation forms. It can rotate forward and backward, and the helical gear adopts a hard tooth surface, which runs smoothly and has a large bearing capacity. The working environment temperature is -10 ℃~40 ℃. Compared with similar products, this product has the characteristics of large speed variation range, compact structure, and easy installation. Can be used as a deceleration mechanism for various mechanical equipment such as metallurgy, mining, lifting, light industry, chemical industry, transportation, and construction. Technical parameters of k series reducer: k series reducer output speed: 0.1~530k series reducer output torque: ≤ 18000N. mk series reducer motor power: 0.12~200KW.

1. Space saving, reliable and durable, high overload capacity, power up to 200KW

2. Low energy consumption, superior performance, and a deceleration efficiency of over 95%,

3. Low vibration, low noise, rigid cast iron box body, gear surface undergoes precision machining such as carburizing heat treatment and gear grinding.

4. Technical parameters: Power: 0.12KW~200KW Torque: 10N · m~58500N · m Output speed: 0.08~263r/min

Scope of use:

The K series reducers are widely used in the transmission fields of light and heavy industry machinery such as metallurgy and mining, petrochemicals, building materials machinery, railway vehicles, port ships, textile printing and dyeing, food packaging, paper printing, lifting and transportation, logistics loading and unloading, agricultural, animal husbandry and fishery machinery, light industry and leather.

Performance characteristics:

The K series reducer motor is integrated with a compact structure, which improves the torque and efficiency of the reducer. It has a wide speed range, good universality, and can adapt to various installation methods. Its performance is safe, reliable, and has a long service life,

1. Box body: HT250 high-strength cast iron, injection molded inner cavity, effectively reducing part wear;

2. Gear: 20CrMo alloy steel, treated with carbonitriding (maintaining tooth surface hardness HRC60 after precision grinding);

3. Flat key: 45 steel, surface hardness HRC50.

Basic model classification of K-series gear reduction motors:

GK. Bottom installation of helical gear - bevel gear reducer

GKA. B foot hollow shaft installation helical gear umbrella gear reducer

GKV. B Foot Spline Hollow Shaft (DIN5480) Diagonal Wheel Reducer

Installation of GKH. B foot hollow shaft locking plate for helical gear bevel gear reducer

GKF. is a B5 flange mounted helical gear bevel gear reducer

GKAF is a B5 flange hollow shaft installation helical gear bevel gear reducer

GKVF is a B5 orchid key hollow shaft installation helical gear umbrella gear reducer

GKHF. B5 flange hollow shaft locking plate installation helical gear bevel gear reducer

GKA. Hollow shaft installation helical gear bevel gear reducer

GKV. Installation of helical gear bevel gear reducer with spline hollow shaft

GKH. Hollow shaft locking plate installation helical gear umbrella gear reducer

GKT. Hollow shaft torsion arm installation helical gear umbrella gear reducer