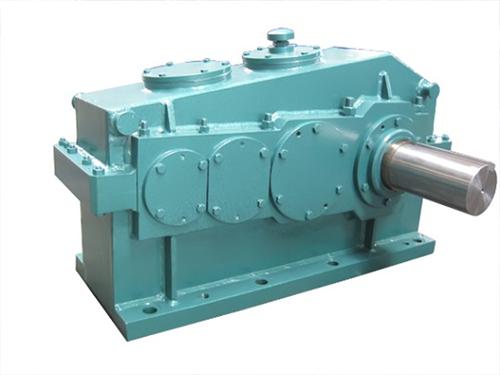

Structural features and self-locking function of worm gear reducer

In many large-scale equipment, planetary gear reducers are used with many functions, among which the planar secondary enveloping worm gear reducer is the worm gear reducer, because the worm gear and worm gear are paired in the application of reducers. There is a worm gear in a reducer, so a worm gear reducer is just a colloquial term for a worm gear reducer.

Structural characteristics of worm gear reducer:

It can achieve a large transmission ratio and is more compact than the helical gear mechanism with staggered shafts. The contact between the meshing tooth surfaces of the two wheels is linear, and its load-bearing capacity is much higher than that of the helical gear mechanism with staggered shafts. Worm transmission is equivalent to helical transmission, and it is a multi tooth meshing transmission, so the transmission is stable and the noise is very low.

Has self-locking properties. When the lead angle of the worm is less than the equivalent friction angle between the meshing teeth, the mechanism has self-locking and can achieve reverse self-locking, that is, it can only be driven by the worm gear, not by the worm gear. If a self-locking worm mechanism is used in its heavy machinery, its reverse self-locking can provide protection.

The structural characteristics and self-locking function of the worm gear reducer result in low transmission efficiency and severe wear. When using worm gear and worm gear meshing transmission, the relative sliding speed between the meshing teeth is high, resulting in high friction loss and low efficiency. On the other hand, the relative sliding speed causes severe wear and heat generation on the tooth surface. In order to dissipate heat and reduce wear, expensive materials with good friction and wear resistance and good lubrication devices are often used, resulting in higher costs and greater axial force on the worm.

Application of self-locking function of worm gear reducer:

In the transmission mode of the reducer, worm gear transmission has characteristics that other gear transmissions do not have, that is, the worm gear can easily rotate the worm gear, but the worm gear cannot rotate the worm gear. This is because the structure and transmission of the worm gear and worm gear are achieved through friction.

The self-locking function of worm gear transmission is very useful in mechanical applications, such as winches, conveying equipment, and so on. However, it is also due to the friction transmission method of worm gear and worm gear that the transmission efficiency of worm gear and worm gear is much lower than that of gear transmission.

Not all worm gear reducers have good self-locking function, and the self-locking function of the worm gear needs to reach a certain speed ratio to be achieved. This is related to the lead angle, which means that the self-locking function of the small speed ratio worm gear is not as ideal.