What are the faults of KA57 spiral bevel gear reducer? How to deal with it?

KA57 spiral bevel gear reducer may experience various faults, and the following are some common faults and their solutions:

Overheating of bearings: Bearings are an important component of gearboxes, and if the temperature is too high, it may be due to bearing failure. The handling method includes checking whether the bearings are loose or damaged, and replacing the bearings in a timely manner.

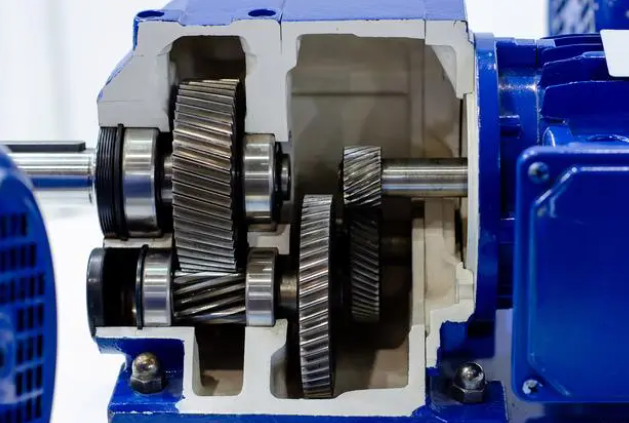

Gear wear: The gears in the reducer may wear out during prolonged operation, leading to a decrease in transmission efficiency. The handling method includes regular inspection of gear wear and timely replacement of severely worn gears.

Poor lubrication: The gearbox requires good lubrication to operate properly, and poor lubrication may cause equipment failure. The handling method includes regular inspection of the lubrication system to ensure that the lubricating oil is sufficient and of good quality.

Installation issue: Incorrect installation position or unstable foundation of the reducer may cause equipment failure. The handling method includes checking the installation position and foundation of the reducer to ensure that it meets the technical requirements.

Overloading operation: If the gearbox exceeds its rated load during operation, it may cause equipment failure. The handling method includes avoiding overloaded operation and ensuring that the equipment operates within the rated load range.

In response to the above faults, it is recommended to regularly inspect and maintain the equipment to promptly identify and address issues. At the same time, it is also necessary to pay attention to the working environment and conditions of the gearbox, strengthen the training and management of equipment operators, and improve their operation and maintenance skills. If encountering a malfunction, it is necessary to promptly contact professional technicians or manufacturers for repair and maintenance.